The robotics market is poised for substantial growth, driven by technological advancements, increasing demand for automation, and strategic investments by key players. By 2030, the market is expected to reach unprecedented heights, with robots becoming integral to various sectors, including healthcare, manufacturing, logistics, and domestic applications. Leading companies like ABB, Yaskawa, and KUKA continue to innovate and expand their market presence, ensuring their leadership positions.

The increased use of robotics is benefiting both consumers and businesses globally, particularly in the industrial sector where automation is reducing production costs and improving efficiency. The demand for industrial robots, such as gantry and SCARA robots, is rising, especially in the US and Europe, with modest price increases expected. Newer robots, including autonomous mobile robots and collaborative robots, are designed to work alongside humans, enhancing tasks like assembly and quality inspection.

In the domestic sphere, service robots are becoming more common, automating household tasks. This category includes popular robot vacuum cleaners and advanced bipedal robots. Notable developments include Tesla Optimus robot unveiled in late 2022 and Boston Dynamics’ bipedal robots developed with the US military. Startups like Figure.AI are also creating generative AI-driven service robots, signaling a potential revolution in the market.

How Big is the Robotics Market in 2030?

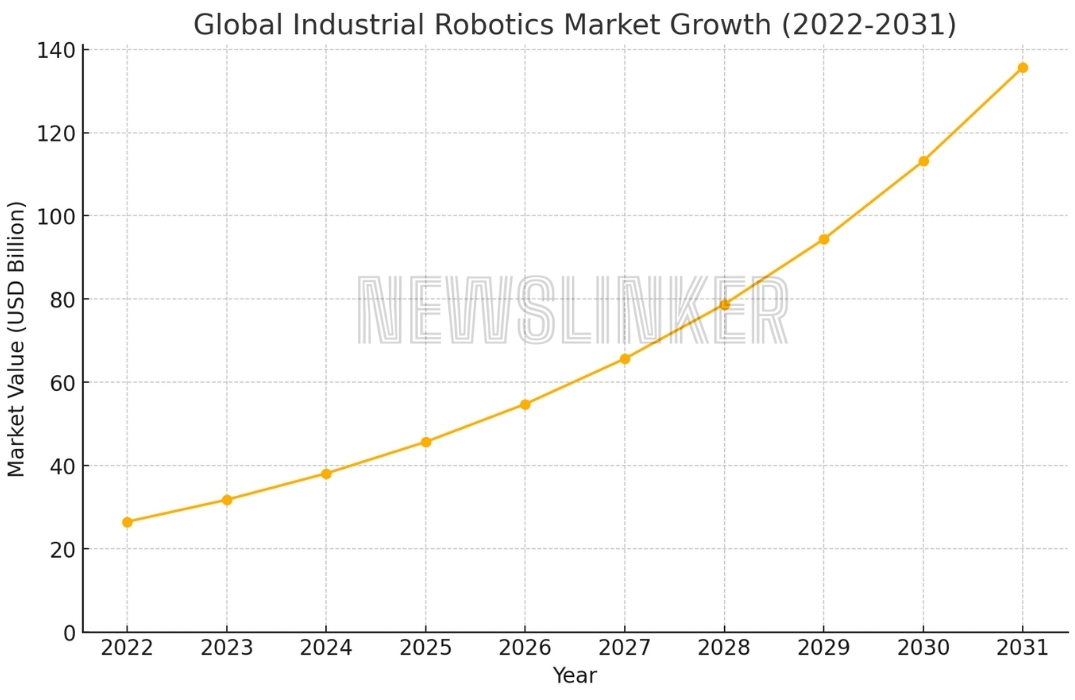

The global industrial robotics market is on a trajectory of significant growth, with projections indicating a substantial expansion by 2030. Valued at USD 26.52 billion in 2022, the market is expected to grow at a compound annual growth rate (CAGR) of 10.5%, reaching an estimated USD 135.68 billion by 2031. This impressive growth is driven by several factors, including the ongoing Industry 4.0 revolution, which emphasizes automation and smart manufacturing, and the increasing adoption of robotics in various sectors such as automotive, electronics, and logistics.

The integration of advanced technologies like machine learning and artificial intelligence (AI) into industrial robots is significantly enhancing their capabilities, thereby boosting their adoption. Furthermore, the advent of 5G technology, with its promise of low latency and high-speed connectivity, is set to further accelerate the use of robotics in industrial applications. The COVID-19 pandemic has also acted as a catalyst, pushing industries towards greater automation to mitigate labor shortages and maintain operational efficiency.

Who is the Leader in the Robotics Market?

China currently leads the robotics market, particularly in industrial robotics, with a significant market share of 20% and revenue of USD 2.9 billion in 2022. This leadership is supported by high demand for automation, strong governmental backing, and advancements in research and development. The Asia-Pacific region, including China, Japan, and South Korea, is experiencing the fastest growth.

Key players like Fanuc, ABB, KUKA, and Yaskawa dominate the industrial segment, holding 56% of the global market. The articulated robot, the most popular type, had a 67% market share in 2022. The industrial robotics market is highly competitive, with several key players dominating the landscape. As of recent data, ABB Ltd. stands out as a leader in the global industrial robotics market, with a significant market share.

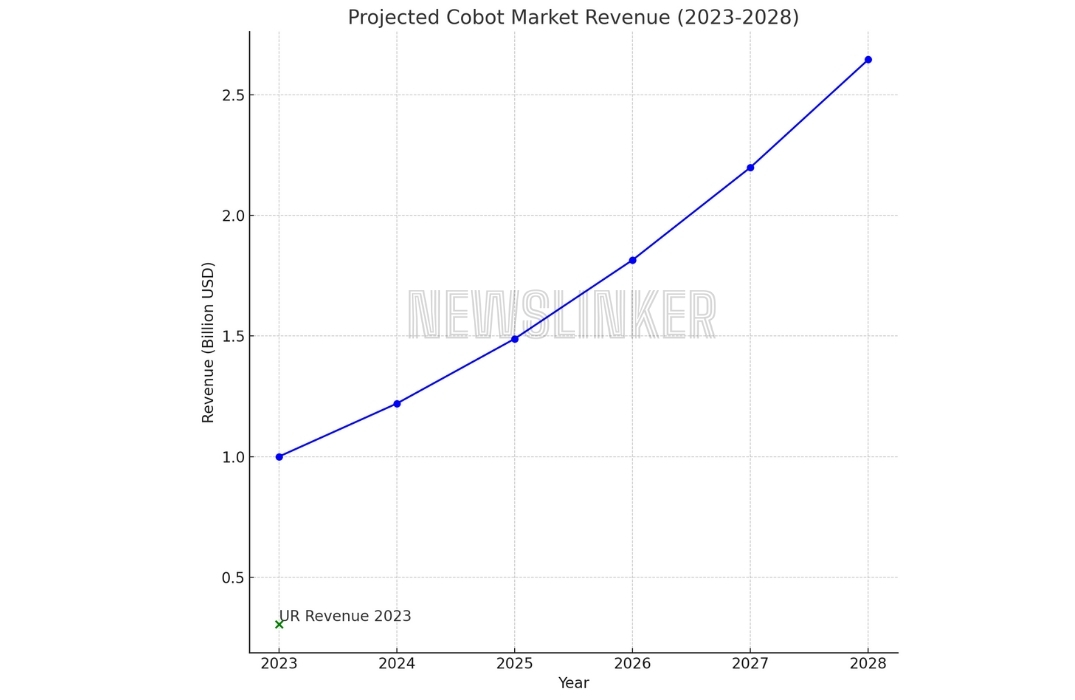

In the service robotics sector, 2022 saw sales of over 158,000 professional service robots and 5 million consumer service robots, reflecting significant growth. Universal Robots leads the collaborative robot market with a 47% share. The cobot market, valued at USD 760 million in 2022, is expected to reach USD 22.6 billion by 2032.

China’s dominance, coupled with innovation from major companies, solidifies its leadership in the robotics market, with continued growth expected globally across various industries.

Cobot Market Size

The global collaborative robot (cobot) market exceeded $1 billion in revenues in 2023, even though demand recovered more slowly than expected post-pandemic, according to Interact Analysis. The market is projected to grow by 22% in shipments in 2024, with annual growth rates exceeding 20% through 2028. Despite challenging economic conditions and supply chain issues, cobot revenue growth was 11.9% in 2023.

What Will Robots Do in 2050?

By 2050, robots are expected to perform a wide array of tasks, fundamentally transforming various aspects of our lives. In the healthcare sector, robots will play a crucial role in patient care, including monitoring, medication delivery, and even performing surgeries with high precision. The advancements in AI and machine learning will enable robots to make autonomous decisions, thus enhancing their effectiveness in complex medical procedures.

In the industrial sector, robots will take over most of the repetitive and hazardous tasks, leading to safer and more efficient manufacturing processes. Autonomous robots will be prevalent in logistics and supply chain management, optimizing inventory handling, order fulfillment, and transportation. The integration of AI will allow these robots to learn from their environment and adapt to new tasks without human intervention.

Moreover, the domestic use of robots will become commonplace. Robots will handle household chores, provide companionship, and assist the elderly and disabled. The concept of smart homes will be fully realized with robots integrating seamlessly with other IoT devices to create a highly automated living environment. In agriculture, robots will perform tasks such as planting, harvesting, and monitoring crop health, thereby revolutionizing food production.

AI Robotics Market

The AI robotics market is experiencing exponential growth, with a projected CAGR of 29.21% during the forecast period. The integration of AI into robotics enhances their capabilities, making them more versatile and efficient. AI enables robots to perform complex tasks with minimal human intervention, thereby increasing productivity and reducing operational costs.

In industrial settings, AI-powered robots are improving production processes through predictive maintenance, fault detection, and quality control. These robots can analyze vast amounts of data to optimize manufacturing operations and ensure high-quality outputs. In healthcare, AI robots assist in surgeries, patient care, and diagnostic processes, providing personalized and precise medical care.

The logistics sector is also benefiting from AI robotics, with autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) streamlining warehouse operations and supply chain management. These robots can navigate through complex environments, manage inventories, and perform material handling tasks efficiently. The continuous advancements in AI are expected to further expand the applications of robotics across various industries.

Which Country is Best for Robotics?

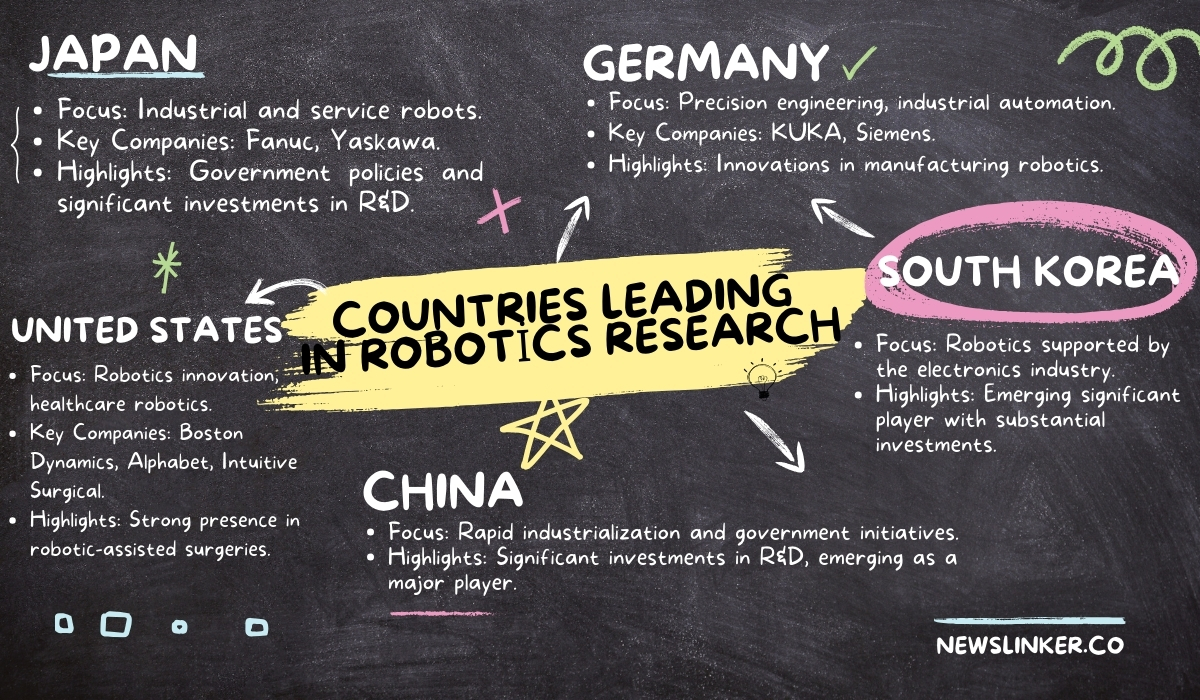

Several countries are leading the charge in robotics research, development, and deployment, each contributing uniquely to the global robotics landscape. Japan is widely regarded as a pioneer in robotics, with a strong emphasis on both industrial and service robots. Japanese companies like Fanuc and Yaskawa are global leaders in industrial robotics, and the country’s commitment to robotics is evident in its government policies and significant investments in research and development.

The United States is another key player, with its robust ecosystem of innovative companies and research institutions. Tech giants such as Boston Dynamics and Google’s Alphabet are at the forefront of robotics innovation, developing advanced robotic solutions for various applications. The U.S. also has a strong presence in healthcare robotics, with companies like Intuitive Surgical leading in robotic-assisted surgeries.

Germany is renowned for its precision engineering and industrial automation, making it a hub for industrial robotics. Companies like KUKA and Siemens are driving innovations in manufacturing robotics, contributing significantly to the country’s industrial prowess. South Korea and China are also emerging as significant players in the robotics market, with substantial investments in robotics research and development. South Korea’s focus on robotics is supported by its strong electronics industry, while China’s rapid industrialization and government initiatives are propelling it to the forefront of the robotics market.

Looking ahead to 2050, the role of robots will further expand, transforming our lives and work environments. The integration of AI will make robots more autonomous, versatile, and efficient, enabling them to perform a wide range of tasks with minimal human intervention. As countries like Japan, the U.S., Germany, South Korea, and China continue to invest in robotics, they will drive the global market’s growth, making robotics an essential component of the future technological landscape.

The Latest Scientific Publications on Robotics

“Dielectric Elastomer Network with Large Side Groups Achieves Large Electroactive Deformation for Soft Robotic Grippers” published in Advanced Functional Materials on July 2024, researchers have developed a groundbreaking elastomer, addressing a significant challenge in dielectric elastomer actuators (DEAs). Traditional elastomers achieve minimal electroactive deformation without prestretch, while those capable of large deformation require complex processing. This new elastomer, featuring a network of large side groups, achieves an impressive 218% deformation without prestretch. The elastomer is rapidly produced by polymerizing a commercial monomer with a large alkyl side group. The repulsion between large side groups extends load-bearing strands, resulting in strain-hardening behavior that prevents electromechanical instability. This advancement enables high energy density, significant output force, and rapid response, making it ideal for soft electroactive grippers capable of handling delicate, complex-shaped objects efficiently.

“A Flexible, Architected Soft Robotic Actuator for Motorized Extensional Motion” published in Advanced Intelligent Systems on July 2024, researchers have introduced a novel, flexible soft robotic actuator designed for motor-driven extensional motion. The actuator features a 3D printed cylindrical handed shearing auxetic (HSA) structure combined with a deformable internal rubber bellows shaft. This design allows linear extension upon torque application from a servo motor. The rubber bellows shaft, while stretchable, resists torsional deflection, effectively transmitting torque. The actuator’s components, noted for their high flexibility, enable adaptive extension even when bent. Mechanical characterization of the actuator shows it achieves a 45% elongation strain and a maximum blocked pushing force of 8 N. Demonstrations include a crawling robot and a sensorized artificial muscle with a microfluidic liquid metal strain sensor. This innovative design approach offers unique benefits such as a compact form factor and user-friendliness, outperforming traditional motorized soft actuators based on HSA assemblies or cable tendon mechanisms.