The automotive sector anticipates significant advancements in electric vehicle (EV) manufacturing by 2025, according to recent insights from ABB Robotics’ Automotive Manufacturing Outlook Survey. This optimism is driven by enhanced production technologies and workforce upskilling, positioning the industry for robust growth in the coming years. Additionally, the integration of advanced robotics is expected to play a crucial role in streamlining EV production processes.

Previous reports indicated a temporary decline in automotive robotics orders, with non-automotive sectors surpassing them in 2020. However, recent trends suggest a resurgence in automotive robotics investment, aligning with the current positive outlook on EV production. This shift underscores the industry’s renewed focus on meeting the increasing demand for electric vehicles through technological advancements.

What Drives the Positive EV Production Outlook?

A substantial portion of survey respondents foresee EV output rising by more than 10% in 2025, with an additional 44% expecting up to a 10% increase. The confidence is partly attributed to improved manufacturing capabilities and the adoption of new production technologies.

“There’s strong evidence that EV manufacturing capabilities are now considerably improved,”

stated Joerg Reger, managing director of ABB’s automotive business line. This sentiment reflects the industry’s readiness to scale up EV production effectively.

Can the Industry Meet 100% EV Production Goals?

Despite the optimistic production forecasts, there is growing skepticism about achieving complete EV production by the 2030-2040 deadlines. Approximately 65% of respondents doubt the feasibility of reaching 100% electric vehicle production within this timeframe. The primary challenges cited include consumer demand fluctuations and inadequate charging infrastructure, which are recognized as significant impediments beyond the manufacturing environment.

How is Robotics Adoption Shaping EV Manufacturing?

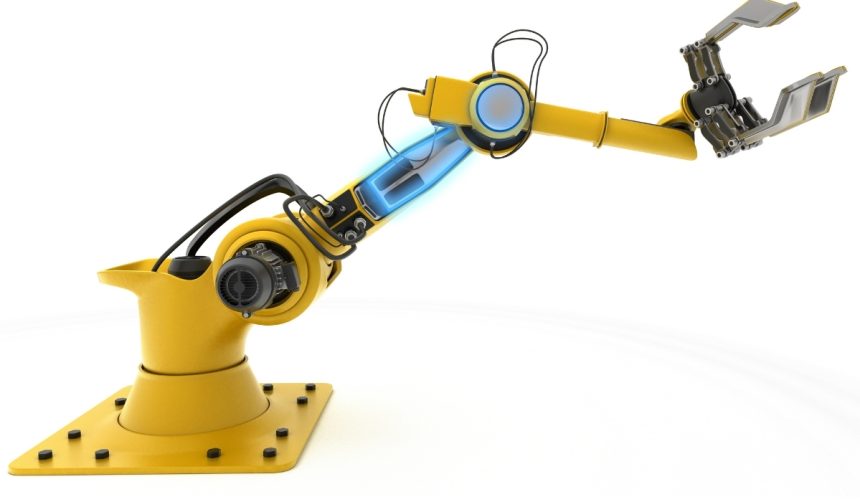

The survey highlights a strong adoption of robotics among new OEMs, startups, and technology specialists, with 63% investing significantly in robotics and automation. Autonomous mobile robots (AMRs) and collaborative robots (cobots) are expected to see the highest increases, facilitating more efficient and flexible production lines. This technological integration is essential for meeting the anticipated growth in EV production and addressing the complexity of manufacturing multiple powertrain types.

Implementing advanced robotics not only enhances production efficiency but also addresses the intricate demands of EV manufacturing. The industry’s focus on robotics is complemented by ongoing efforts to overcome barriers such as high initial costs and infrastructure development.

Emphasizing the importance of strategic investment in automation, the survey suggests that the automotive industry‘s embrace of robotics is pivotal for sustaining growth and competitiveness in the evolving EV market. This strategic focus is expected to drive innovation and operational excellence, ensuring that manufacturers can meet both current and future demands effectively.