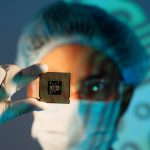

Samsung Electronics has advanced preparations to launch trial equipment operations at its semiconductor plant in Taylor, Texas. This facility is designated to produce Tesla’s upcoming AI5 chip, a component designed for next-generation automotive artificial intelligence. Construction work on the Taylor site is nearing its end, and the plant has rapidly become a central node for Samsung’s U.S. semiconductor strategy. Area developments have garnered interest as Texas continues positioning itself as a national technology hub, drawing talent and substantial investments to the region. The plant’s progress has been closely watched by both industry analysts and local officials, given the increasing demand for advanced chip manufacturing in North America.

Over the past year, Samsung’s plans for the Taylor facility have shifted from early-stage site development to expedited equipment installation. Reports from late 2023 primarily focused on supply chain adjustments and expanding workforce capacity. The most recent details highlight Samsung’s emphasis on EUV lithography equipment and direct production support for Tesla’s specialized chip needs. Unlike prior updates, the current timeline now identifies March as the start of trial machinery use, alongside plans to obtain a temporary occupancy certificate to enable early manufacturing.

What is Samsung’s Strategy for the Taylor Facility?

Samsung aims to initiate trial runs with extreme ultraviolet (EUV) lithography tools at its Taylor factory as soon as March, an essential step before mass production. By securing a temporary permit, the company anticipates starting production activities while final construction tasks continue. The facility, spanning roughly 4.85 million square meters, currently employs around 7,000 workers, signaling considerable operational readiness. A representative from Samsung commented,

“Our objective is to support global customers by delivering advanced semiconductor technology from our U.S. base.”

How Does Tesla’s AI5 Chip Align with Its Broader Technology Plan?

The new chip, named AI5, is part of Tesla’s accelerated AI hardware development plan for its electric vehicles and autonomous systems. CEO Elon Musk recently stated that the AI5 design is almost complete and indicated that work on its successor, the AI6, has already begun. Musk noted,

“We are committed to advancing our AI processors on a nine-month development cycle,”

pointing to Tesla’s intention to maintain a rapid pace. The integration of Samsung’s 2nm process technology indicates a focus on higher efficiency and processing speed, compared to TSMC’s parallel effort using a 3nm protocol for another version of the AI5 chip.

Why are Multiple Chip Suppliers Involved?

Samsung and Taiwan Semiconductor Manufacturing Company (TSMC) are both due to fabricate separate versions of the Tesla AI5 chip. This dual-sourcing model aims to provide stability in supply and allows Tesla to benchmark performance between two leading foundries. The involvement of both companies also reflects the broader industry trend of diversifying semiconductor suppliers to manage risks associated with global logistics and production hiccups. Apart from technology, proximity to Tesla’s primary U.S. manufacturing operations provides logistical advantages for chips produced in Texas.

Developments at Samsung’s Taylor facility mark a significant point for both partners as Tesla continues to push its AI hardware roadmap. While prior news centered mostly on site preparation and permitting delays, the recent pivot to equipment testing suggests strong progress. Samsung’s focus on advanced EUV machinery and temporary production clearance illustrates adaptability in project management, minimizing time to market for Tesla’s custom chips. For observers and investors, tracking differences in the chip fabrication processes and the pace of ramp-up at each supplier will yield insight into competitive dynamics in automotive AI semiconductors. Companies considering supply chain partnerships in North America could see Samsung’s approach as a reference, especially for large-scale, customized electronics production.