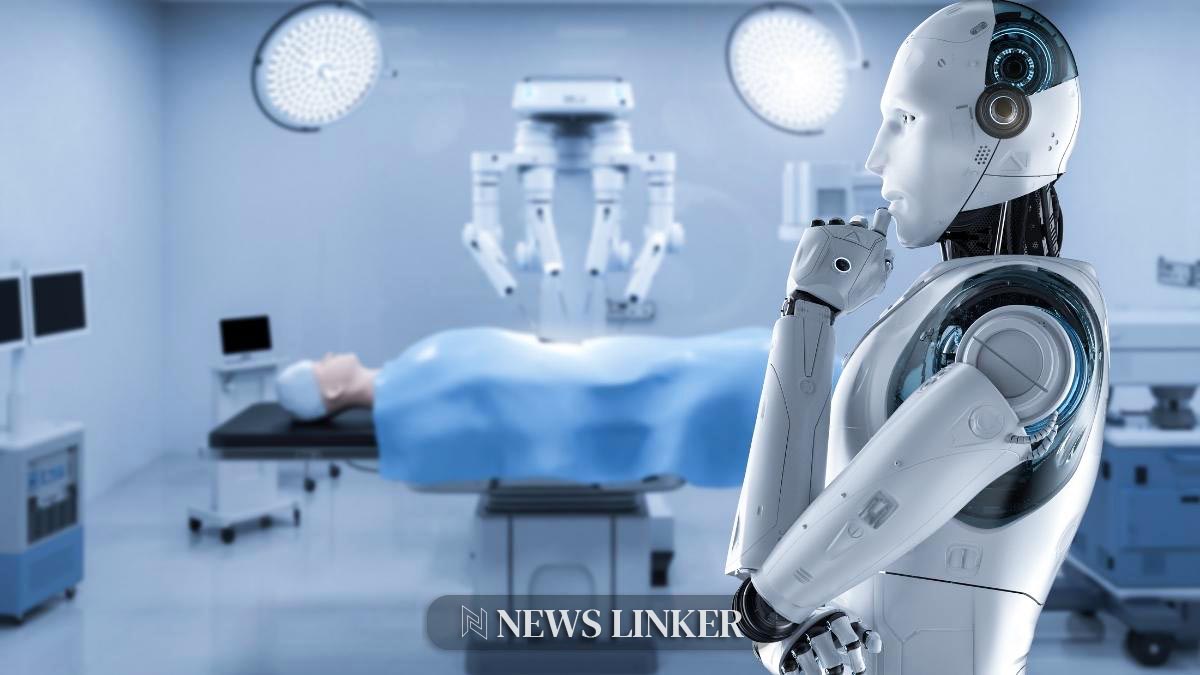

The burgeoning interest in humanoid robots has led to a collaboration between Figure AI, based in Sunnyvale, California, and BMW Manufacturing. The agreement involves testing Figure AI’s 01 humanoid robot at BMW’s Spartanburg plant in South Carolina. Since its inception in 2022, Figure AI has quickly progressed from its stealth mode exit in early 2023 to securing this significant opportunity.

Humanoid Robot Integration in Automotive Manufacturing

The Spartanburg facility, where BMW employs 11,000 people over an 8 million square foot area, is responsible for assembling several BMW models. The plant’s significance is highlighted by its status as the largest automotive exporter in the United States, having produced over 6.3 million BMWs in the past three decades.

Figure AI described the collaboration as milestone-based, with the initial phase focused on identifying simple logistics tasks for the robot, such as moving bins and boxes. The company’s founder and CEO, Brett Adcock, remains optimistic about the robot’s capabilities and the potential to increase the number of humanoid robots at the plant if the initial trials are successful.

BMW’s spokesperson expressed excitement about the new technology but clarified that the application of humanoid robots is still being evaluated, with no fixed timeline established. The automaker also emphasized the robots’ potential to address ergonomic issues with their superior dexterity and mobility compared to traditional robotic systems.

Commercial Prospects for Humanoid Robots

Figure AI has not only attracted BMW but also amassed a customer backlog, showcasing the humanoid robot’s first public steps in October 2023. The company’s growth is indicative of the increasing interest and development of humanoid robots, with companies globally, including China, aiming to commercialize humanoids for a variety of applications.

The broader application of robotics in BMW is evident through its numerous awards and innovations, including the use of exoskeletons, collaborative robots, and autonomous mobile robots. These advancements demonstrate BMW’s commitment to integrating cutting-edge technology to enhance their manufacturing processes and maintain a competitive edge.