Industrial plants frequently face dangers and costs from undetected gas leaks, which can affect safety, operational budgets, and compliance efforts. Today, ANYbotics AG unveiled a Gas Leak and Presence Detection system as an add-on for its ANYmal quadruped robot, aiming to automate leak detection in environments where manual checks can fall short. ANYmal’s advanced sensors and data transmission capabilities provide real-time alerts and comprehensive facility coverage, potentially reducing risks to human inspectors and minimizing environmental impact. While safety and cost-efficiency remain core concerns for industry operators, integrating robotic inspection in hazardous locations is rapidly shifting from optional to essential. The new capability also integrates with ANYbotics’ Data Navigator platform, creating a continuous feedback loop for predictive maintenance planning.

Earlier discussions regarding robotic gas detection have typically centered on single-purpose solutions or static monitoring devices, which often require frequent manual recalibration or offer limited mobility in crowded facilities. The inclusion of modular payloads and autonomous navigation seen in the ANYmal platform distinguishes it from much of the prior technology. Whereas previous reports highlighted slow or partial transitions to robotic systems, recent feedback suggests broader acceptance, particularly when these systems can lower insurance costs and enable regulatory compliance through automated data collection. The focus has also shifted from simply identifying leaks to quantifying risk, supporting sustainability commitments, and providing asset-centric insights for targeted maintenance.

What Technical Features Support Accurate Leak Detection?

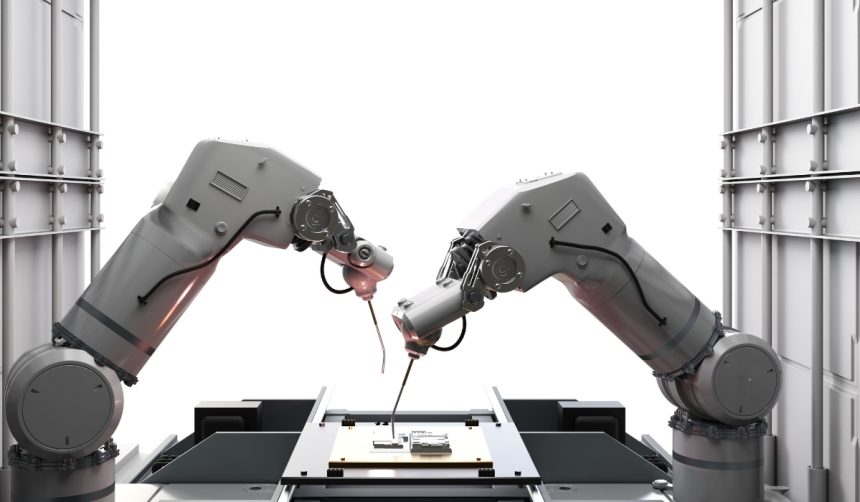

ANYmal offers modular sensor payloads, including integrated gas detectors and a 360-degree acoustic imaging camera, which allow for precise localization and measurement of gas leaks in otherwise inaccessible areas. By capturing acoustic signatures associated with leaks, the robot identifies not only the presence but also the source and severity of emissions. The system can distinguish between a wide range of gases, such as steam, hydrocarbons, and toxic compounds, addressing the diverse challenges of industrial installations. The platform’s sensor interchangeability also brings on-site calibration, adapting the robot to various mission requirements efficiently.

How Does Data Integration Improve Maintenance Strategies?

Inspection data collected from ANYmal’s sensors are centralized within the Data Navigator software, where emission events are mapped onto facility floorplans. Maintenance teams receive contextual insights—including quantifiable leak rates and environmental data—that can drive targeted responses and foster predictive maintenance planning. This aggregation of multi-sensor data supports adherence to environmental standards by providing documentation and operational trends over time. The platform accommodates users ranging from robot operators to maintenance engineers, tailoring information delivery to each role’s needs and responsibilities within an industrial setting.

Do End Users Experience Operational and Safety Gains?

Customers in sectors such as energy, mining, and petrochemicals, including companies like Outokumpu Oyj and DSM-Firmenich AG, have already implemented the Gas Leak and Presence Detection capability in their facilities. Reports from these users indicate measurable reductions in unplanned shutdowns and maintenance overhead, as automated inspections allow for more frequent coverage of hazardous and hard-to-reach locations.

“Gas Leak Detection fits into our data and maintenance strategy and gives us peace of mind so we can focus on value-creating tasks,”

stated a technical leader at DSM-Firmenich, underscoring the system’s impact on daily operations and resource allocation.

ANYbotics’ expansion of ANYmal integrates advanced mobility, routinely collecting high-fidelity inspection data under both autonomous and teleoperated modes. The addition of the Gas Leak and Presence Detection system is positioned as a subscription-based upgrade, with a flexible approach through a robotics-as-a-service (RaaS) model starting at under $1,000 monthly. Investors have demonstrated confidence in this direction, backing the company’s global growth and continued integration of hardware and software, with an emphasis on certification and security.

By bringing adaptable gas detection and environmental sensing into a mobile robotic platform, ANYbotics has advanced the use of autonomous inspection in high-risk industrial scenarios. Users can adapt sensor packages for specific site needs, relying on consolidated inspection data for asset management and compliance. Automating hazardous inspections with ANYmal not only minimizes human exposure but also supports improved maintenance accuracy, quick response to anomalies, and reduced downtime. For operators dealing with environmental audits, emissions regulations, and aging infrastructure, deploying robotic inspection platforms like ANYmal can enhance predictive maintenance and lower ongoing operational expenses by providing constant monitoring and timely actionable insights.