Industrial automation continues to expand, with manufacturers seeking solutions that blend efficiency with adaptability. Ati Motors, recognizing this evolving landscape, has now introduced the Sherpa Mecha, a dual-armed mobile manipulator designed for manufacturing environments. By prioritizing utility rather than mimicking the human form, Ati Motors pursues increased capability on factory floors. The robotics sector has long debated the merits of functional versus lifelike robot designs, and Ati Motors brings a new perspective to the discussion. The Sherpa Mecha aims to address complex tasks often encountered in dynamic manufacturing settings.

Other announcements of the Sherpa Mecha over recent months highlighted experimental trials and research partnerships, with a focus on collaborative robot-human interactions. Now, the roll-out of the commercially available version signals a transition from selective innovation pilots to scalable deployments. Earlier models were limited to controlled factory tests, but the latest iteration is positioned for integration into a broader range of operations alongside competing products from Reflex Robotics, RoboForce, and Kinisi Robotics offering similar features.

How Does Sherpa Mecha’s Design Benefit Manufacturing?

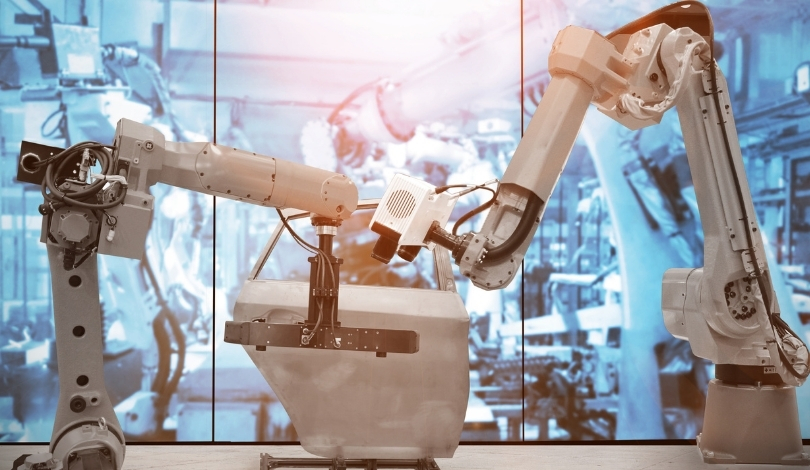

The Sherpa Mecha features two articulated arms and a wheeled base, prioritizing practical effectiveness rather than anthropomorphic accuracy. Ati Motors developed this new robot using proven actuation systems and a modular artificial intelligence backbone, which supports various manufacturing tasks such as machine tending, material transport, and inspection duties. The engineering process involved collaborative efforts with research labs, academic institutions, and industrial partners, resulting in a robot tested under demanding factory conditions for reliable performance and straightforward integration.

What Differentiates Sherpa Mecha Among Mobile Manipulators?

While several robotics firms produce dual-armed, wheeled manipulators, Sherpa Mecha distinguishes itself by focusing on seamless incorporation into manufacturers’ existing automation lines. The robot is designed for adaptability, allowing clients to customize tools and functionalities to fit their specific application needs. As Ati Motors CEO Saurabh Chandra stated,

“We’re solving real manufacturing needs across the world.”

This ability to tailor its operational capabilities sets the Sherpa Mecha apart as a utility-driven solution rather than a generic platform.

How Does Sherpa Mecha Fit Into Ati Motors’ Larger Portfolio?

Ati Motors offers a broad selection of autonomous mobile robots under the Sherpa brand, including tugs, pallet movers, and lifting platforms. These robots cater to various payload requirements and logistical challenges in industrial settings. The launch of the Sherpa Mecha complements this lineup by introducing a more dexterous, manipulatory element to Ati Motors’ range. The company highlights the new robot’s capacity to integrate with existing tools, stating,

“Mecha is now the next step: incorporating deeper into our customers’ ecosystems to assist with information flow, automation, and integration. Automation has moved outside the box.”

Attendees at Product Day 2025 first saw a preview of the Mecha, and its development reflects shifts in robotics from experimental human-robot collaboration to practical, everyday applications. By commercializing Sherpa Mecha following successful trials, Ati Motors invites manufacturers to consider mobile manipulation as a practical supplement to fixed automation. Compared to prior reports covering research phases and early prototypes, the current offering is more robust and accessible for businesses aiming to upgrade their automation strategies.

The trend in industrial robotics increasingly favors modular, functional machines over those designed primarily as human imitators. Sherpa Mecha’s dual-arm, tool-forward approach underlines this shift, providing users with flexibility in automating repetitive industrial tasks. Companies evaluating automation platforms should assess their specific workflow requirements, considering how the Sherpa Mecha’s capabilities—such as machine tending and heavy part transportation—might fit their operational goals. The progress from development to product launch illustrates the maturation of mobile manipulation in manufacturing. Readers interested in integrating such solutions should analyze competitive offerings, weigh adaptability, and engage directly with providers like Ati Motors for tailored deployment strategies.