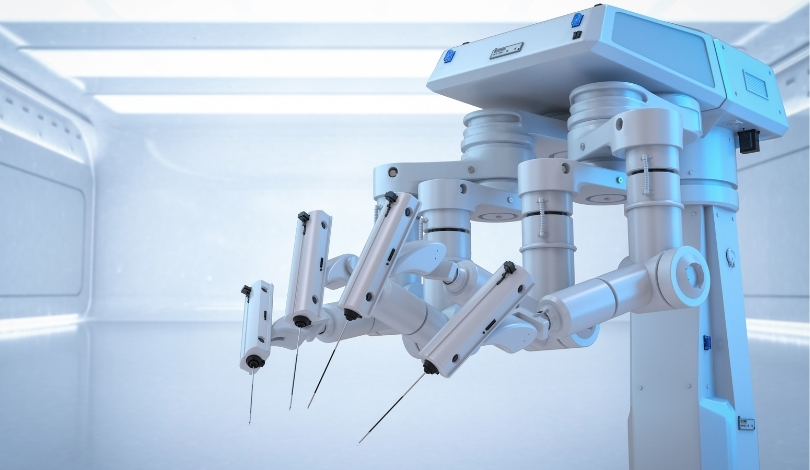

Brightpick, a leader in warehouse automation, expands its robotics lineup with the introduction of the Giraffe robot. Designed to maximize storage capacity and operational efficiency, Giraffe is set to transform warehouse logistics. This addition comes as the demand for automated solutions in e-commerce and medical distribution continues to grow. Warehouses are increasingly seeking advanced technologies to meet the surge in order fulfillment demands.

Brightpick has consistently innovated in the mobile manipulation sector. The company’s previous products, including the Autopicker, have been widely deployed across the U.S. and Europe, enhancing warehouse operations. The introduction of Giraffe marks a significant step in increasing storage density and optimizing space utilization without the need for extensive infrastructure changes.

How does the Brightpick Giraffe integrate with Autopicker?

The Brightpick Giraffe complements the existing Autopicker system by retrieving totes from upper-level shelves and delivering them to lower levels where Autopickers can efficiently handle picking tasks. This seamless integration allows warehouses to store items up to 20 feet high, tripling storage density compared to manual operations and doubling it against the Autopicker alone.

What benefits does Giraffe bring to warehouse operations?

Giraffe enhances warehouse operations by significantly increasing storage capacity and optimizing the placement of inventory. “Brightpick has always excelled at providing high throughput and maximum labor savings at a competitive price,”

said Jan Zizka, CEO of Brightpick.

The robot’s ability to quickly retrieve and return totes ensures higher efficiency and better utilization of warehouse space.

What are the planned deployments for Giraffe?

Brightpick plans to deploy Giraffe in two U.S. companies this year, expanding its presence in the American market. One major e-commerce retailer will implement 25 Autopickers and six Giraffes to boost their daily pick rate and storage capacity. Additionally, a medical wholesaler will use Giraffe alongside Autopickers to enhance the fulfillment of critical medical products.

By integrating Giraffe with Autopicker, Brightpick offers a versatile solution that addresses both high throughput and high storage needs. This combination allows warehouses to handle a larger volume of orders without compromising on efficiency or requiring significant structural changes.

Brightpick continues to demonstrate its commitment to innovation by showcasing the Giraffe prototype at upcoming industry events. The company’s strategic expansions and product enhancements position it well to meet the evolving demands of modern warehousing.

The deployment of Giraffe not only increases operational efficiency but also provides warehouses with the flexibility to adapt to changing inventory demands. As automation becomes increasingly integral to supply chain management, solutions like Giraffe will play a crucial role in maintaining competitive advantages.

The Brightpick Giraffe represents a significant advancement in mobile warehouse robotics, offering practical benefits that extend beyond simple automation. Its ability to enhance storage density and integrate seamlessly with existing systems makes it a valuable asset for modern warehouses aiming to optimize their operations.