In a recent study, Zebra Technologies Corp. revealed that only one out of every six manufacturers fully comprehends their own processes. The report highlighted that 61% of manufacturers foresee artificial intelligence (AI) driving growth by 2029, showing a significant rise from 41% in 2024. Zebra’s study, conducted by Azure Knowledge Corp., involved extensive surveys among top executives and IT leaders across various sectors, including automotive, electronics, and pharmaceuticals. For comprehensive insights, visit the 2024 Manufacturing Vision Study.

Digital Transformation Drives Visibility

Despite the emphasis on digital transformation, achieving a fully connected factory proves challenging for manufacturers. Zebra Technologies emphasized that visibility is crucial for optimizing efficiency and quality on the production floor. However, only 16% of manufacturing leaders globally reported having real-time, work-in-progress (WIP) monitoring across their entire process. The push for increased visibility by 2029 faces hurdles, including disagreements between IT and OT on investment priorities.

Manufacturers are aiming to address these challenges by implementing advanced technologies. The study found that 86% of leaders struggle to keep up with technological innovation and securely integrate new devices and sensors. Zebra’s systems are designed to provide higher security and manageability while using new analytics to enhance business performance.

Technological Integration Augments Workforce

Zebra’s study also discovered a strategic shift towards integrating AI and other technologies to augment the workforce over the next five years. A notable 73% of respondents plan to reskill labor for data and technology usage, while 70% intend to enhance worker efficiency through mobility-enabling technology. Manufacturers are increasingly deploying tools such as tablets, mobile computers, and workforce management software to facilitate this transition.

Across the C-suite, IT, and OT sectors, leaders recognize that labor initiatives need to go beyond productivity improvements. Ongoing development, retraining/upskilling, and career path development are ranked high in priority to attract future talent. The focus is on creating a well-connected and efficient manufacturing floor where technology aids human workers.

Comparing this recent news to earlier reports, the emphasis on AI and digital transformation remains consistent. However, the current study shows a stronger inclination towards workforce augmentation and the integration of advanced tools like mobile computers and wearables. This indicates a shift in strategies from merely adopting new technologies to ensuring these tools complement and enhance the human workforce.

Earlier reports mostly focused on the challenges of digital transformation, such as high costs and technical barriers. The current findings highlight that while these challenges persist, there is now a more concerted effort towards overcoming them with specific technology implementations. This evolution in strategy underscores the growing recognition of the critical role technology plays in modern manufacturing.

Automation Enhances Quality Control

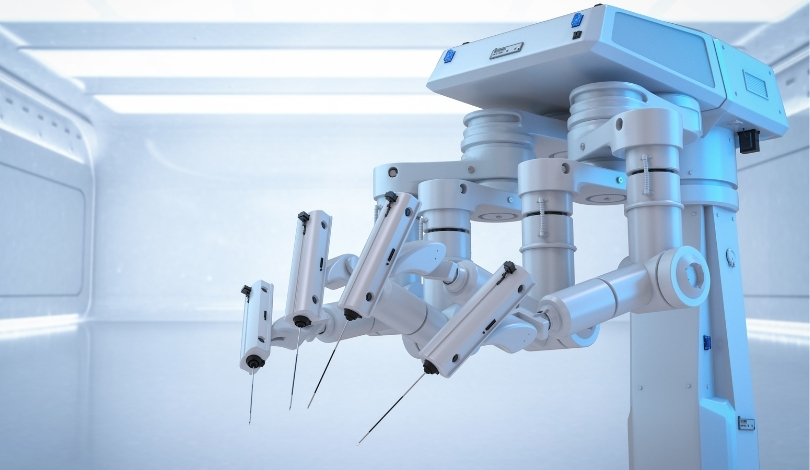

The pursuit of quality in manufacturing has intensified as companies seek to do more with fewer resources. According to Zebra and Azure’s survey, significant quality management issues include real-time visibility, compliance with new standards, data integration, and traceability. Over the next five years, manufacturers plan to implement technologies such as robotics, machine vision, and radio frequency identification (RFID) to address these challenges.

These automation initiatives aim to empower the workforce with high-value tasks and improve flexibility on the plant floor. The survey findings indicate that these decisions are driven by the need to meet service-level agreements (SLAs), enhance workforce efficiency, and integrate new technologies seamlessly into existing operations.

Emerging technologies like robotics and AI are enabling manufacturers to utilize data more effectively, allowing them to identify and prioritize issues and projects for maximum efficiency gains. Zebra Technologies offers systems that connect data, assets, and people intelligently. Their extensive portfolio includes software, mobile robots, machine vision, and automation solutions, backed by over 50 years of experience in the industry.

The company supports over 10,000 partners in more than 100 countries and counts 80% of the Fortune 500 companies among its clients. By hosting webinars and other educational events, Zebra continues to guide manufacturers in overcoming the challenges of digital transformation and automation, ensuring they stay competitive in a rapidly evolving market.