As humanoid robots increasingly enter the workforce, the demand for scalable manufacturing solutions has grown significantly. To meet this demand, Figure AI Inc. has introduced BotQ, a state-of-the-art facility dedicated to high-volume production of humanoid robots. Positioned to produce up to 12,000 units annually, BotQ is a pivotal development in making advanced robotics more accessible across various industries. This move not only signifies a boost in production capacity but also reflects the company’s strategic shift towards in-house manufacturing to maintain stringent quality standards.

Figure AI has continuously evolved its manufacturing strategies since its inception, focusing initially on prototype development and early market trials. The establishment of BotQ marks a transition from experimental phases to large-scale production, demonstrating the company’s ability to adapt and scale in response to industry needs. This progression highlights Figure AI’s commitment to innovation and its readiness to support the growing integration of humanoid robots in different sectors.

Scaling Production with BotQ

BotQ’s inaugural production line is engineered to fabricate up to 12,000 humanoid robots each year. By centralizing manufacturing operations, Figure AI can better oversee the build process and ensure consistent quality across all units.

“Bringing our manufacturing in-house allows us to maintain tighter control over the production and quality of our robots,”

a company spokesperson stated. This centralized approach is designed to optimize efficiency and streamline the delivery of high-functioning robots to the market.

Strengthening the Supply Chain

Developing a robust supply chain has been critical for Figure AI, especially given the complexities of humanoid robot components. The company has invested in designing most of its robot’s modules internally, including actuators, motors, and battery packs. Additionally, Figure AI has partnered with global suppliers to ensure scalability, aiming to support production volumes that could reach 100,000 robots in the coming years.

“Our strategic partnerships with specialized vendors enhance our ability to scale rapidly and meet increasing demand,”

the company noted.

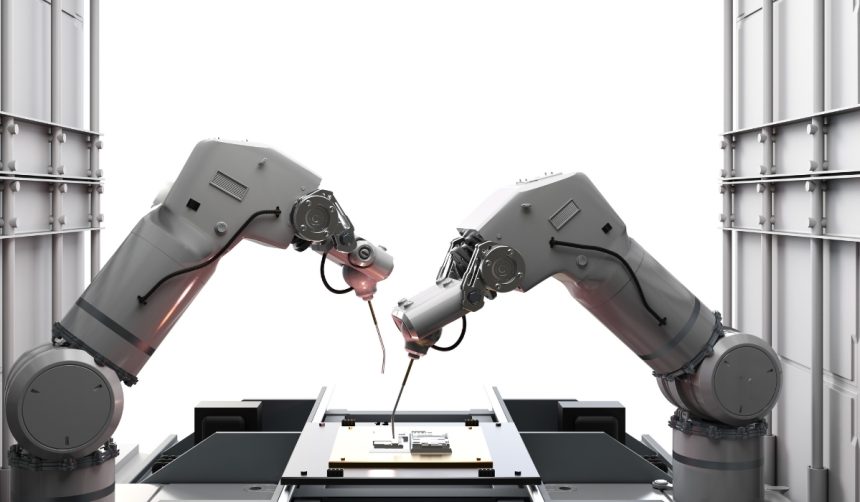

Integrating Automation in Manufacturing

Automation plays a crucial role in Figure AI’s manufacturing strategy. By implementing automated systems for tasks such as grease dispensing and battery cell testing, the company enhances both speed and precision in production.

“Automation allows us to perform repetitive tasks more accurately and efficiently than manual processes,”

explained a manufacturing engineer at Figure AI. This integration of AI-driven automation not only accelerates production timelines but also minimizes human intervention in labor-intensive processes.

BotQ is set to incorporate humanoid robots into its own assembly lines, enabling a self-sustaining production environment where robots build other robots. This innovative approach is expected to significantly reduce production times and costs, positioning Figure AI as a leader in the mass production of humanoid robots. The facility’s advanced manufacturing execution system (MES) and integration with IoT devices ensure real-time monitoring and optimization of the production process, further enhancing operational efficiency.

Implementing BotQ not only increases Figure AI’s production capacity but also sets a new standard in the robotics industry for high-volume manufacturing. By focusing on automation, supply chain robustness, and centralized production control, Figure AI is well-equipped to meet the escalating demand for humanoid robots. These advancements are likely to accelerate the adoption of robotics across various applications, from industrial automation to customer service.