Warehouses and factories are seeing a rapid rise in robotic automation, with facilities relying more on autonomous equipment for tasks like material handling, inspection, and collaboration with human teams. The efficiency and safety of these automated systems now hinge on their ability to sense the environment accurately and in real time. Increasingly complex scenarios, such as reflective surfaces and unpredictable human movements, have exposed the limitations of widely used cameras, radar, and time-of-flight lidar sensors. Meeting industry needs for scalable, affordable, and highly precise autonomy requires new approaches, particularly for harsh or dynamic operating environments.

Earlier reports primarily focused on traditional lidar and vision systems struggling in situations with variable lighting, dust, and overlapping sensor signals, particularly when multiple robots worked in close proximity. Those approaches typically required a combination of different sensors to approach the needed level of reliability. However, recent developments with chip-based frequency modulated continuous wave (FMCW) lidar now promise substantial improvements in both performance and affordability, offering a new path forward for mass deployment in industrial settings.

How Does FMCW Lidar Address Industrial Sensing Needs?

FMCW lidar technology, adopted by Voyant Photonics in products like the Carbon lidar system, leverages frequency-modulated laser light to determine both distance and velocity of objects. Unlike older ToF sensors, FMCW devices offer robust operation in challenging lighting and environmental conditions, providing detailed 3D data while avoiding cross-talk issues. This allows robots to understand object locations and movement within a single scan, leading to faster and safer operations. As explained by Voyant,

“Our lidar solution provides not just the depth but also precise velocity data for every object in the scene.”

What Enables Scalable Production and Deployment?

The adoption of silicon photonics in FMCW lidar manufacturing supports mass production using semiconductor foundries, mirroring processes already established in the computing industry. Integrating all components onto a single chip reduces the cost, size, and variability of the sensors, allowing deployment in robotic arms and mobile platforms. This approach also simplifies calibration and improves reliability.

“Silicon photonics enables us to build consistent, high-performance lidar units at volumes never before possible,”

noted a spokesperson from Voyant Photonics.

Where Are the Key Adoption Areas for This Technology?

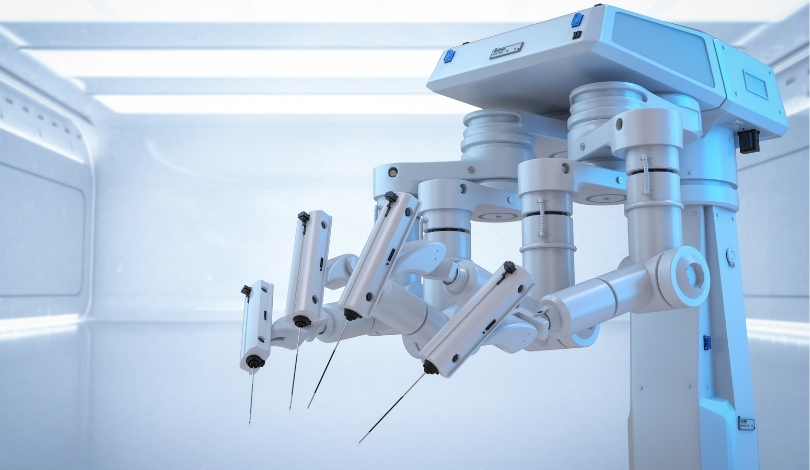

Industrial operations benefit from FMCW lidar’s strengths in applications requiring precise 3D sensing and motion detection. In pallet handling, the technology helps guide forklifts with sub-centimeter accuracy, even when dealing with glossy or wrapped loads. Robotic arms can better manage object picking and manipulation, overcoming issues caused by varied packaging. Autonomous mobile robots (AMRs) use the sensors to reliably map and traverse complex warehouse layouts, minimizing navigation errors, and increasing operational uptime. The sensors also provide improved human detection, boosting safety during machine-human collaboration.

Making FMCW lidar affordable and scalable marks a shift in the economics of industrial robotics, lowering the entry barriers for wider adoption. As manufacturing and logistics facilities further automate, sensors that combine compact design, high fidelity, and resilience to environmental changes will set new standards. Compared to legacy approaches, integrated lidar chips could support broader deployment of “Physical AI”—where perception and intelligence merge to allow machines greater autonomy and adaptability.

Facilities planning to adopt automation should pay close attention to evolving sensor technologies. Integrating FMCW lidar can alleviate issues stemming from poor lighting or reflective surfaces and reduce sensor fusion complexity. When considering upgrades, key decision points include compatibility with existing robotic platforms, robustness in diverse operational scenarios, and long-term scalability. Companies seeking to maximize productivity while containing costs may find chip-based lidar systems like those from Voyant Photonics fit these criteria, especially as wafer-scale manufacturing brings prices down. Vigilance about standards and interoperability will help operators future-proof their investments as sensor markets develop further.