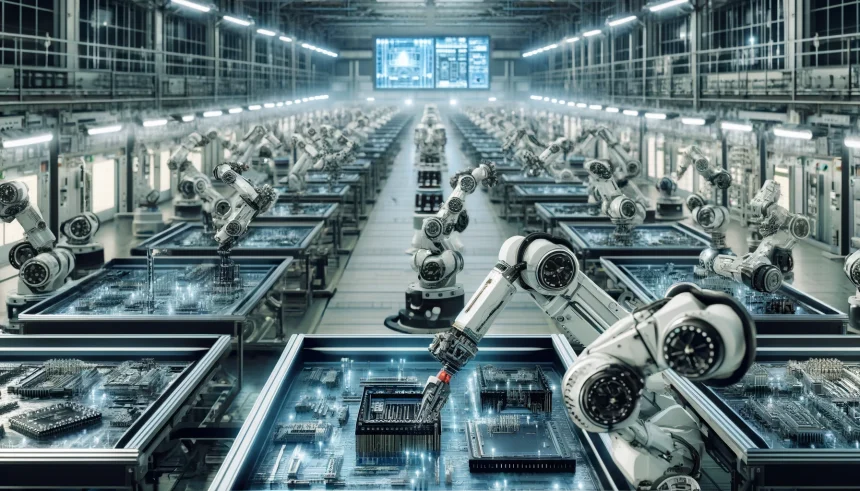

Mitsubishi Electric Automation Inc. introduced the ARIA robotic workcell, expanding its automation solutions. The company designed ARIA to address critical industry challenges, such as labor shortages and productivity demands. ARIA’s flexibility and mobility make it suitable for various applications within a facility, offering a solution to maintain quality standards efficiently.

ARIA, or Automated Robotics Industrial Assistant, is a pre-engineered workcell launched by Mitsubishi Electric Automation. It features a payload capacity of up to 13 kg and a reach of 1,503 mm. ARIA was launched to provide a cost-effective and customizable automation system suitable for diverse industrial requirements.

Mitsubishi Electric Automation has previously launched various robotic solutions, including a series for heavier payloads and longer reach. These previous models were designed to handle larger workpieces and expand automation opportunities further. The introduction of ARIA reflects an ongoing commitment to enhancing automation capabilities, catering to different industrial needs.

Comparing past launches with the new ARIA model shows a focus on flexibility and mobility. Previous models emphasized handling capacity and reach, while ARIA’s modular design and ease of integration target operational efficiency. This evolution in product design highlights Mitsubishi’s strategy to address both specialized and broad-spectrum industrial applications.

Model Variants

ARIA comes in two main models: the Standard Base and the Machine Tool Base. The Standard Base is designed for applications requiring high flexibility and mobility, while the Machine Tool Base is tailored for CNC mill, lathe, and Swiss applications. Both bases are compatible with Mitsubishi’s collaborative, vertical/articulated, and SCARA robots, enhancing their versatility.

Included Features

ARIA includes an FX5 programmable logic controller, a 120V external outlet, casters with jackscrews, and a network switch with an external Ethernet port. Other features include an operator station with a button panel and floor mounting brackets. Additional accessories, such as preprogrammed software, RT ToolBox3, MELFA Works for simulation, MELFA Safe Plus, Force Sensor, and high-performance teach pendants, are also available.

Mitsubishi’s ARIA robotic workcell represents a strategic development targeting critical industry needs. By offering flexible and mobile automation solutions, ARIA aims to address pressing challenges such as labor shortages and productivity demands in industrial settings. The added versatility through standard and machine tool bases, along with comprehensive accessories and software, ensures ARIA can adapt to various applications. This approach reflects Mitsubishi’s ongoing efforts to enhance industrial automation and maintain quality standards across different sectors.