As global industries confront rapid shifts, American companies are ramping up their adoption of advanced robotics to keep pace with China’s manufacturing and climate technology sectors. With household names like BYD and CATL already shaping China’s electric vehicle boom, the US seeks actionable strategies for advancement. Companies such as Terabase Energy are at the forefront, employing robotics to double labor productivity in solar installation. Many experts now point to robotics as essential not only for economic growth but also for the efficient development of green technologies, especially as labor shortages loom in sectors critical to decarbonization efforts.

Several years ago, analysis highlighted China’s rapid scale-up in automation and industrial robotics as a catalyst for its clean tech sector. US firms then mostly focused on limited deployments or strategic partnerships but lacked coordinated large-scale investment. Current trends demonstrate a shift: an influx of venture capital and notable startups focusing on autonomous systems, especially in climate-related fields. This marks a contrast with earlier hesitation and underinvestment, and now ongoing efforts are more closely aligned with those seen in leading global markets.

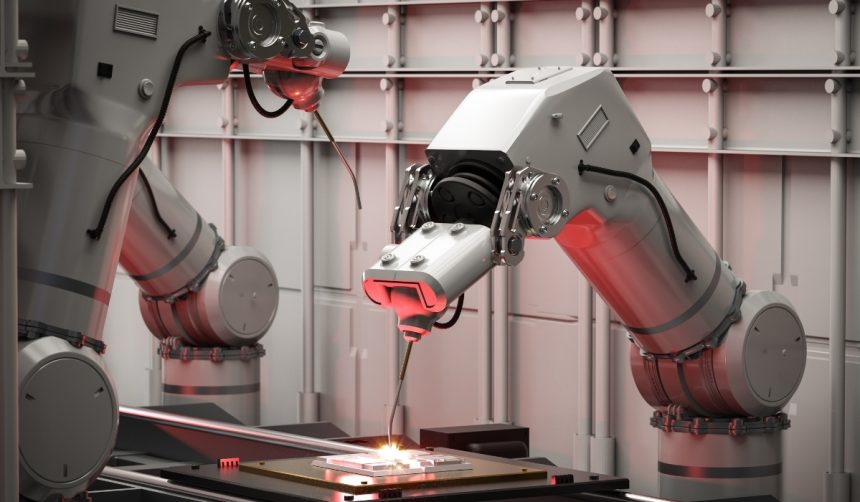

Why Are Robotics Seen as Essential to US Manufacturing?

Manufacturing within the United States faces a growing labor shortfall. The Manufacturing Institute has projected that more than two million industrial jobs may remain unfilled through 2033, potentially costing the US economy one trillion dollars annually. Automation and robotics, as seen in companies like Terabase Energy, are regarded as key to not only bridging this gap but also keeping domestic production competitive. US startups attracted about $6.1 billion in robotics venture capital last year, reflecting a wider acceptance of this approach across industries.

Can Robotics Meaningfully Advance Climate Goals?

Robotics are increasingly linked to decarbonization efforts by supporting resource efficiency and taking on complex or hazardous tasks across energy, infrastructure, and land management. Examples include Pyka’s autonomous electric aircraft for emission-reduced cargo transport and Kodama Robotics’ work in wildfire prevention.

“American startups are already leveraging robotics to tackle some of the most pressing environmental challenges,”

stated a Terabase Energy spokesperson. This growing capability is evident in new and maturing sectors such as battery manufacturing and large-scale renewables, where automation has produced measurable productivity and cost advantages.

What Lessons Can the US Draw From China’s Strategy?

China’s leadership in industrial and climate technology stems from coordinated public and private investment in robotics, producing economic opportunities as well as environmental improvements nationwide. The US has demonstrated similar innovative capacity, yet it has not executed a unified strategy.

“We simply need the strategic vision and commitment to make it happen,”

commented a senior representative at Prelude Ventures. The intersection of climate action and industrial strategy has become more apparent, with each reinforcing growth prospects for the other when robotics adoption is prioritized.

The outlook for US robotics in manufacturing and green technology remains promising but hinges on sustained investment, national coordination, and readiness to learn from global best practices. While labor shortages are a significant challenge, they can act as a catalyst for faster technology adoption. Robotics’ potential to meet both productivity and decarbonization targets provides companies and policymakers with a pragmatic path forward. For businesses exploring automation, focusing on scalable, high-impact deployments in sectors facing acute labor and climate demands is likely to yield the greatest returns. Staying informed about both public policy and private initiatives in robotics will be critical for firms looking to maintain or gain a global competitive edge in a rapidly changing industrial environment.