Servo motor control systems typically operate in one of three essential modes: torque, speed, and position. Each mode can be individually controlled to suit different applications, with some requiring multiple modes within the same operation. However, traditional servo systems often face difficulties in switching modes mid-operation due to potential spikes or drops in winding current, which can disrupt motion performance.

Servo motors and controllers with the capability of instantaneous mode switching provide a solution to this issue. This advanced feature allows for seamless transition between control modes without interrupting the motor’s movement. The technology is akin to bumpless switching, traditionally used in PID control, but has been adapted for use in servo motor control.

These advanced servo systems utilize a nested loop control structure, continuously monitoring feedback from all control signals. This approach ensures that unconnected control loops can continue to develop as though they are connected, enabling smooth mode transitions and stabilization of the output control signal.

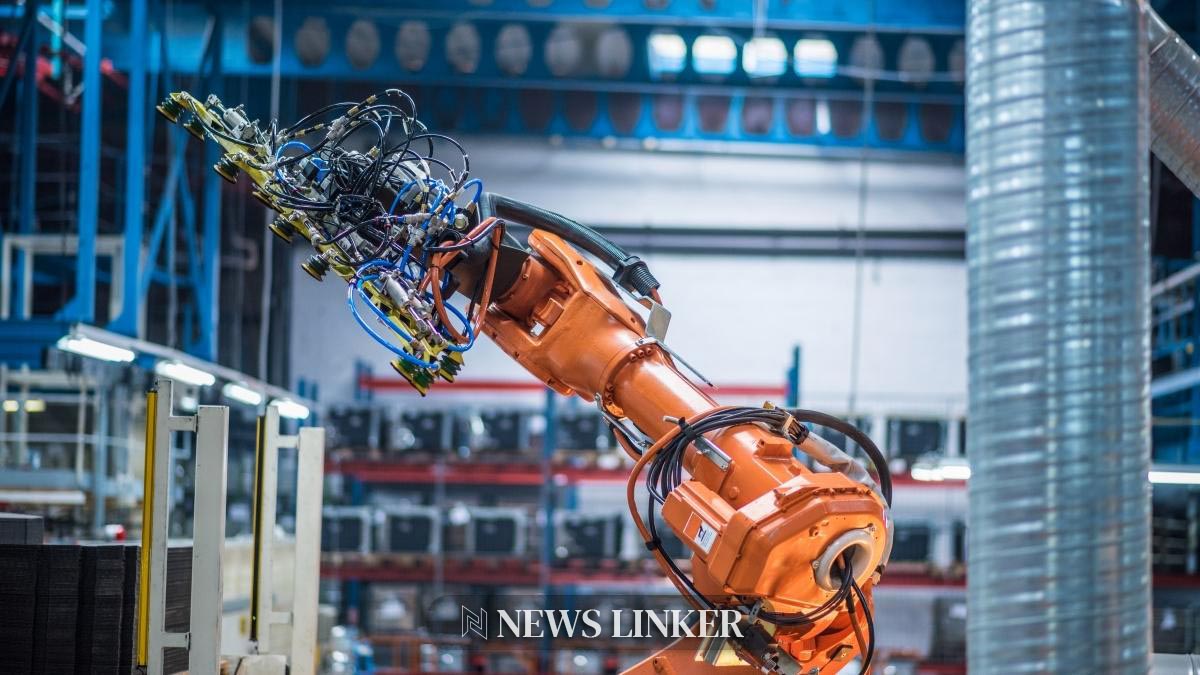

Instantaneous mode switching offers significant benefits in various sectors, such as industrial automation and manufacturing. The seamless transitions preserve settings and enhance stability and performance, which is crucial for maintaining product quality, operational efficiency, and advanced control algorithm implementation.

The principles underlying instantaneous mode switching are based on field-oriented control (FOC) and a triple cascade loop configuration, which regulates different system aspects such as current, speed, and position. This creates a cascading effect where the output of one loop becomes the setpoint for another, contributing to the motor system’s overall stability.

Instantaneous mode switching is particularly effective in applications that require precise control and stability, such as cobots in feeding or insertion tasks, automated centrifuge systems, and spin rinse dryers (SRDs) for semiconductor wafers. These examples illustrate how the capability enhances processes by allowing a smooth transition between speed and position control modes without disrupting ongoing operations.

2. This advancement allows seamless changes between torque, speed, and position modes.

3. Instantaneous mode switching benefits various industrial and manufacturing applications.